SOLUTION

Accumulated rich experience in the research and production of high-precision, high-density, and high reliability printed circuit boards

SOLUTION

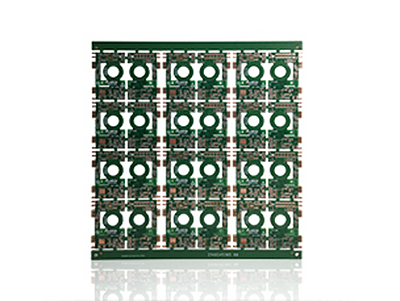

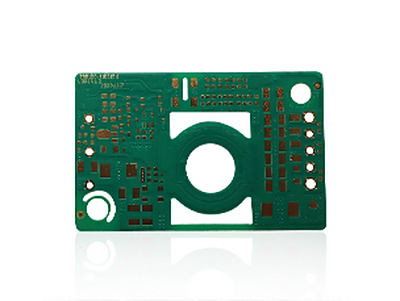

Thick copper plate process solution

Product Introduction and Process Features

Thick copper plates are mainly high current substrates, which are generally high-power or high-voltage substrates. They are commonly used in automotive electronics, communication equipment, aerospace, network energy, planar transformers, power converters, and secondary power modules. The development of thinness and miniaturization in electronic products urgently requires PCBs to have higher thermal conductivity, and the application of thin core thick copper multilayer boards is more widespread. The advantages of thick copper: Thick copper plates (≥ 3oz) have the ability to carry large currents, reduce thermal strain, and have good heat dissipation.